Nuclear Waste Vitrification

Nuclear Waste Vitrification, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gctzc6tejpjbfq J8d5w Xuir7xo3fhzlg102sfmuphqlna7afny Usqp Cau Nuclear Family Of 1950 Nuclear Bomb In Japan Name

A systematic approach typically incorporates.

Nuclear family of 1950 nuclear bomb in japan name. It has been used for hlw immobilization for over 40 years in most countries that have a nuclear power program including france germany. Waste is mixed with glass forming chemicals in a furnace to form molten glass that then solidifies in canisters thereby immobilizing the waste. Different nuclear fission products activation products minor actinides and residual uranium and plutonium not recovered during processing.

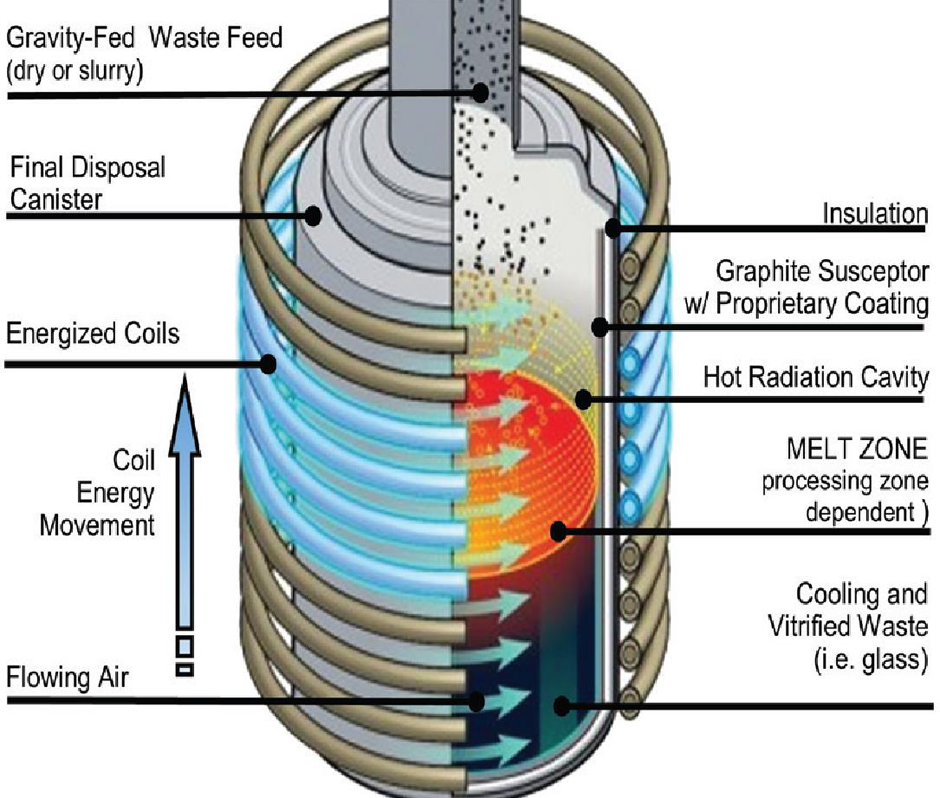

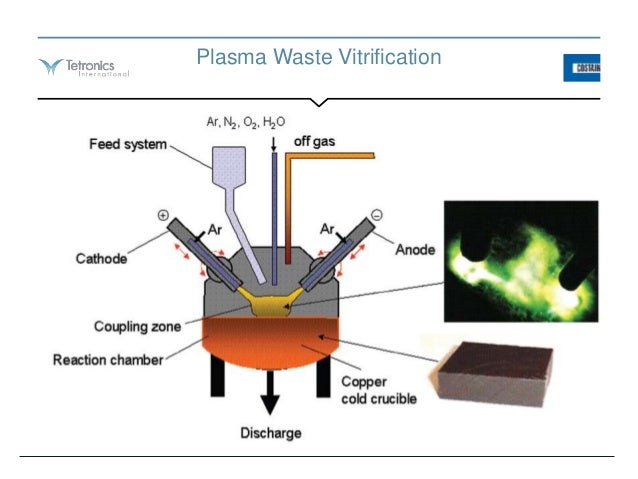

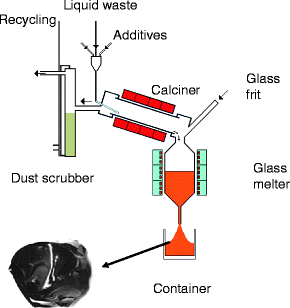

Vitrification is used in disposal and long term storage of nuclear waste or other hazardous wastes in a method called geomelting. Vitrification is a process used to stabilize and encapsulate high level radioactive waste. In the vitrification process radioactive waste is mixed with a substance that will crystallize when heated eg sugar sand and then calcined.

Waste storage buildings at the savannah river site doe 2014. Calcination removes water from the waste to enhance the stability of the glass product. Radioactive waste is a type of hazardous waste that contains radioactive materialradioactive waste is a by product of various nuclear technology processes.

As the world fossil fuel reserves diminish alternate energy sources will become increasingly important. Vitrification as a means of stabilising radioactive waste has been investigated in the uk since the beginnings of the nuclear industry in the 1950s initially using natural soils as the base materials for glass formulation see lutze 1988. Each countrys nuclear waste management policy and its national regulations also influence the approach taken.

Vitrification of nuclear waste linda thompson november 28 2010 submitted as coursework for physics 240 stanford university fall 2010. However the high melting temperatures 1500 0c required in order to produce homogeneous bubble free. Industries generating radioactive waste include nuclear medicine nuclear research nuclear power manufacturing construction coal and rare earth mining and nuclear weapons reprocessing.

One of the most commonly discussed forms of alternative energy is nuclear power. The wvp uses a two stage design based on the continuous french avh. Waste vitrification process and for the storage of vitrified waste produced from this process.

In the uk highly radioactive ha liquor from the reprocessing of spent nuclear fuel is converted into a borosilicate glass at the sellafield waste vitrification plant wvp yielding a stable and durable waste form suitable for long term storage and subsequent disposal. One method of long term storage and disposal involves the processing and transformation of the spent fuel into a glass a technique known as vitrification. Conditioning processes such as cementation and vitrification are used to convert waste into a stable solid form that is insoluble and will prevent dispersion to the surrounding environment.